|

|

|

About

us

Kaiser (Singapore)

is an ISO 9002 certified company established in 1988. Throughout the years,

Kaiser has remained at the forefront of technology. To meet consumers'

needs for high-end products in an age of rapidly advancing manufacturing

technologies, Kaiser has and continues to expand its work in the field

of precision engineering technology.

Today, we integrate our traditional precision manufacturing technologies

with other leading techologies to develop a wide range of high-performance

products such as wireless communication networks components, advanced machining

components, advanced engineering plastics components, oil and gas components.

|

|

|

|

|

|

|

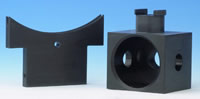

RF

Wireless Components

Kaiser

develops all types of high-level RF-components/devices. These

are standard and custom design flanges, carriers, seal frames

and housing for power devices, circuit and packages ranges

for RF, Power, Laser Diode, Microwave and Hybrid Packages

application.

|

|

|

|

|

click

to view specifications

|

|

|

|

|

|

|

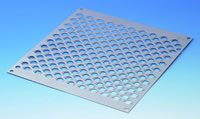

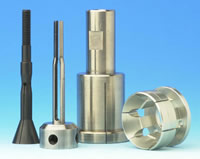

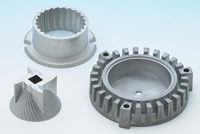

Advanced

Machining Components

Kaiser

has a full line of machining equipment such as state-of-the-art CNC

Mazatro Control Machines, Mitsubishi WireEDM, Hitachi WireEDM, Kemet

Double Lapping machines and High speed Machining centre with 3-D machining

capabilities to produce high precision machining components.

|

|

|

|

|

|

|

|

|

|

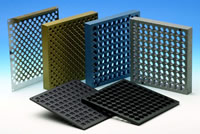

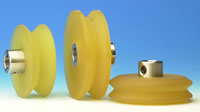

High-Precision

Engineering Plastics

Kaiser's

plastics machining division continues to undergo rigorous development

to stay ahead of the anticipated market needs.

New advanced materials with exceptional high-temperature, chemical and

mechanical wear resistance can be explored for special industrial needs.

|

|

|

|

|

|

|

|

|

Oil

& Gas Components

Kaiser's

capability and experience in manufacturing Oil and Gas components using

material such as Inconel 718, 17-4PH and AISI 410 and other carbon steel

not only provide cost competitiveness but of high quality in the Oil

and Gas field. Option surface treatment such as Nitriding, Tungsten

Carbide coating are available with lapped surface as low as 2 Helium

Light Band.

|

|

|

|

|

|

|

|

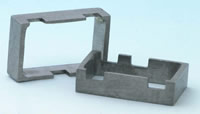

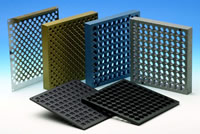

Powder

Injection Moulding (PIM)

Kaiser division of PIM is the latest line of product line

to serve the manufacturing of high precision metals parts,

small intrigue geometrical parts and close tolerances.

This technology is capable of repeatability of high volumn

precision metal parts. |

|

|

| Advantages

of PIM

|

-

High Strength

- Good

Tolerances

- High

intricate and complex geometric

- Elimination

of sub-assemblies

|

|

|

|

|

|

|

|

Contact

Us

For further

information, please contact:

Headquarter

Singapore

Kaiser Precision Engineering PTE LTD

Address:

50 BUKIT BATOK STREET 23,

#04-03/04

MIDVIEW BUILDING,

SINGAPORE 659578

Contact:

TEL: 65) 65678-770

FAX: 65) 65678-955

Email: sales@kaiser-precision.com.

|

Overseas

Offices

China

Kaiser Technology (Shanghai)

Rm 104, No. 34, Lane 815

Taolin Road, Shanghai 200135 China

Email: china@kaiser-precision.com

Korea

Kaiser Technology (Korea)

Ma-Dong 4306, Jung Ang Circulation Complex

1258 Gurobon-Dong, Guro-Gu

Seoul 152-721 Korea

Email: korea@kaiser-precision.com

|

|

|

Enquiry

|

|

|